Concrete has tremendous versatility and is utilized for a variety of different projects from superstructures to pool patios.

If poured and cared for correctly, concrete can last a very long time – long enough to survive a couple generations of bloody knees and chalk art.

However, concrete is not invincible to weathering by the elements. Just like untreated wood rots, untreated concrete spalls.

To learn more about how spalling can cause foundation failure, check out our exhaustive Ultimate Guide To Foundation Repair.

Spalling can ruin the structural integrity of the concrete and compromise any supported loads.

In this article, we are going to touch on:

- What is spalling?

- What causes spalling?

- Areas at Higher Risk of Spalling

- Spalling Repair Options

What is Spalling?Spall is a verb indicating to break (concrete, rock, stone, or ore) into diminutive sections. Concrete Spalling is the breakdown of concrete via natural weathering and/or chemical reaction that results in sections of cement chipping off the main body – often resulting in fractured, compromised concrete. |

Spalling looks like pitted acne scarring and breaks off in flecks which can expose rebar. These divots vary in diameter and depth but can be thicker than 5 inches and just under an inch in depth.

Spalling can be caused by:

- Subpar quality concrete

- Improper curing / poor finishing techniques

- Bond failure in two-course construction

- Electrochemical reactions (such as from de-icing salts)

- Corrosion/oxidization of reinforcing rebar (due to water exposure)

- The wear and tear of the freeze-thaw cycle

*Note on the Freeze Cycle –

Contrary to popular opinion, concrete is porous. Consequently, freezing can be a major contributing factor to spalling if you live in colder climates.

Many products have been developed to coat over your concrete, placing an impermeable waterproof barrier between your driveway and the elements.

Without a coating, freezing soaks into the capillaries of the cement and can expand (ice expands water by 9%).

Over the years, this ice-thaw cycle can weaken and crack up the top layer of your concrete – resulting in ugly indentations and exposed aggregate.

This is not a particularly prevalent issue for Southern Californians or Central Arizonians – however, we’d be remiss not to touch on the subject.

Remember kids: De-icers can ruin your driveway without an epoxy, polyurea, or similar coating.

Check out our article: Concrete Coatings: Epoxy Vs. Polyurea.

Areas at higher risk of Spalling

- The Coast – salt-laden air is particularly astringent and exacerbates rust. This is because of salts. The salts mix with the rain and penetrate the porous concrete.

- Northern States – states that utilize rock salt during the winter months for road maintenance. The salt sticks to cars and melts off in home driveways, wreaking havoc on flatwork.

- Cities – Cosmopolitan areas with a significant amount of pollution (such as sulfate and sulfide and other caustic compounds) have a similarly damaging effect to salt mixing with water, ultimately making it much easier to reach and corrupt rebar.

Also read our blog – How To Repair Your Concrete Foundation That’s Crumbling

Oxide Jacking

Oxide Jacking is the technical term that is responsible for many spalling situations.

The biggest source of spalling we see in the foundation repair industry is rusted rebar.

When moisture makes its way to the reinforcing rebar, this poses a serious threat to your foundation.

Rust expands, biting into your foundation, and, occasionally breaking off entire pieces from your footing.

In short, spalling can affect anything constructed of concrete – but we most often see it in conjunction with foundation failure due to foundation settlement or foundation heave (both of which are caused by expansive soil).

Fun Facts with Brian – Rust can expand the original metal to up to 7 times its original thickness, exerting a tremendous amount of pressure, occasionally resulting in as much as 9000 psi.

Spalling Repair Options

- R&R your Concrete Slab

- Patch the pitted area (utilizing a color matching compound)

- Resurface with new concrete (not the best option if the rust is not addressed first)

Dalinghaus Delamination Repair Method

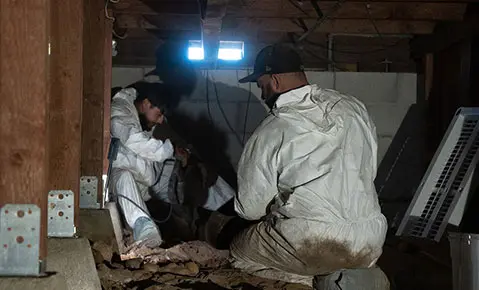

Here at Dalinghaus, we utilize a specific repair method to repair spalling concrete –

This procedure is for a non-bowing wall crack repair and is intended to provide confining strength over the patched surface as well as make up for any strength deficiencies related to section loss of corroded reinforcing steel. 0.6700 Notes 1.) All loose material must be removed from the crack locations. 2.) If corrosion is present on the reinforcing steel, clean rebar and patch void with 9,000 psi non-shrink grout. 3.) If corrosion has resulted in more than 10% section loss, chip void along rebar and add additional reinforcing bar to wall prior to patching. 4.) Ensure that the existing reinforcing steel is cleaned during this process and that the new rebar extends a minimum of 12″ beyond the corrosion. 5.) Epoxy new reinforcing steel in place and let set until cured. 6.) Once cured patch void with 9,000 psi non-shrink grout. 7.) Once patching material has set, prepare surface to a minimum concrete surface profile CSP-3 as defined by ICRI 310-2R. 8.) Install SRS-660BI over the affected area extending a minimum of 18″ beyond the crack. 9.) Follow all manufacturers instruction on the preparation, installation, and curing of the material. 10.) For all material installed on the exterior, coat the CFRP with a coating appropriate for the conditions to provide UV protection. 11.) Cover back up and match finish (stucco/cement/paint) |

Let Dalinghaus Repair Your Spalling

Here at Dalinghaus, we believe preventative maintenance is the best form of maintenance. It’s a good idea to coat your driveways with water-resistant formulas.

And, if you do have spalling, get it treated ASAP in order to maintain the structural integrity of the concrete as much as possible.

If you live in Southern California or Central Arizona and would like one of our foundation specialists to come out and inspect your cement, click the link below –