We live in a fallen world – in a world of cracked foundation footings, rusted rebar, and severe concrete spalling, all of which can threaten the integrity of your foundation. Compromised foundation footings result in structural and property value decline.

We know – scary. Obviously, you’d like to keep your property value up and enjoy a structurally sound home, but how exactly do you repair a cracked footing?

We’re so glad you asked. We have over 100 years of combined experience in the foundation repair industry, and we are here to help you make the best decisions possible regarding busted footings and foundation repair in general – whether you work with us or not.

What Causes Slab Foundation Cracks?

As mentioned above, slab cracks are always indicative of a deeper problem. Slab cracks are the signs and symptoms, not the proverbial virus. But this symptom can be tricky to find. The majority of homes do not have an exposed slab throughout the entirety of the house (unless you’re going for a 70’s chic vibe). So, you might not know immediately that there is an issue. Odds are, you’re more likely to trip over the crack than see it first.

When slab on grade foundations crack, they bulge or bow, resulting in an uneven walking space. It might feel like a concrete tumor has developed underneath your shag carpet, kitchen tile may chip and break, your linoleum flooring may lift upwards. Often a layer of flooring covers and camouflages the crack, flooring which needs to be removed to expose the fissure.

- Foundation settlement – The slab on grade foundation sinks and settles into incompetent, non-load-bearing soil (such as loam and clays), exerting stress onto the home’s foundation, framing, and throughout the interior of the home. The uneven support causes the slab to crack, further compromising the structural integrity of the home.

Other signs and symptoms:

- Drywall cracks

- Stucco cracks

- Sloped floors

- Leaning chimneys

- Windows and doors that are difficult to open/close

- Foundation heave – The slab on grade foundation is pushed upward by expansive soil (such as loam and clays), driving an incredible amount of force upward. This extreme pressure can crack up and through the slab on grade foundation.

- Root damage – Trees, bushes, and shrubbery can sink roots underneath your home’s foundation. As the roots develop and grow, they push against your slab, resulting in some gnarly concrete cracks.

- Poor initial mud mix – Incorrectly mixed mud/concrete can result in slab on grade cracks. These cracks tend to be small and hairline, often referred to as crazing.

- Concrete spalling – Extreme and chronic moisture can result in water damage/spalling, which can make your foundation more susceptible to slab on grade cracks. Spalling usually results in pitted and “scarred” concrete.

After the cause of the crack has been determined, an appropriate plan of action can be drawn up. Remember, cracks are a symptom, not a direct issue. Foundation settlement and foundation heave, specifically, will require more than a simple carbon fiber staple repair to fix the cracked slab.

Foundation settlement generally requires steel pier systems (push and helical piers) to secure the foundation to competent, load-bearing soil in a procedure referred to as underpinning. To learn more about underpinning, read our article What is Underpinning (Definition, History, & Types).

What is Carbon Fiber and Why is it Helpful for Repairing Cracked Footings?

Carbon fiber is utilized for structural reinforcement and is a popular option for bowing basement walls, spalling-proofing caissons, and patching cracked foundation footings. Carbon fiber is so strong it is stronger than aramid Kevlar, which is utilized for body armor.

There are various brands of carbon fiber currently on the market for foundation repair – all with various levels of quality. We utilize Fortress carbon fiber due to its high tensile strength.

We’ve all heard the expression what doesn’t combust you makes you stronger – that’s definitely the case here. The oxygen starvation process results in a little black filament (a burned piece of carbon fiber rayon that did not combust). These filaments are incredibly strong.

These filaments (about the size of a human hair) are collected in little “toes” – which are sections of 60,000 filaments. This translates into about 15,000 pounds worth of tensile strength. Tensile strength is the resistance of a material to breaking under tension.

Essentially, it’s a mini rebar. This technology was created by NASA and the US military due to its strength and lightweight usage.

Note – a “composite” is a carbon fiber that is comprised of a matrix (such as epoxy or polyurethane). This strengthens, seals, and typically acts as an adhesive for the carbon fiber and the application site.

We utilize Fortress’ carbon fiber because of its amazing strength. This carbon fiber consists of rayon baked at 1200 degrees Fahrenheit. It’s then starved of oxygen so it can’t combust.

In short, we use Fortress carbon fiber due to its:

- High tensile strength

- High strength to weight ratio

- Non-corrosive (great for concrete reinforcement)

- Rigid – 10% the reinforcement of steel making it perfect for strengthening and reinforcing.

All the qualities listed above make carbon fiber perfect for:

- Column Wrapping

- Slab reinforcement and repair

- Crack repair

- Beam reinforcement

- Seam reinforcement and waterproofing

- Disaster mitigation

This carbon fiber is unilateral, not woven together. Weaving takes away around 30% of carbon fiber’s tensile strength, making it a poor choice for structural reinforcement.

The unilateral carbon fiber is cut to size, dipped in epoxy, and then smoothed over the crack. The epoxy creates a chemical bond to the substrate (which is stronger than the concrete itself). So, the strong carbon fiber is “cemented” to the failing footing. It’s not going anywhere.

Think of epoxy as a heavy industrial glue. It’s utilized on airplanes. If it’s air safety approved, your patched foundation footing is in good hands.

Other quality brands of carbon fiber include:

- Rhino Carbon Fiber

- Structural Rienforcement Solutions

- Grip-Tite Manufacturing Company

No matter what brand you go with, you want to ensure they have high tensile strength so the carbon fiber can hold your repair in place for years to come.

The Steps to Carbon Fiber Wrap Repair

When you take carbon fiber (which is a staggering 15,000 pounds worth of tensile strength) and apply it with epoxy (which itself averages 300 pounds of tensile strength) – you have a hulk grade strength patch and amazing adhesive.

So, now that you are familiar with the material, let’s go through the steps. It’s important to know the steps to carbon fiber wrap repair so you know what to expect during the repair.

Step 1 – Expose the Crack/Footing

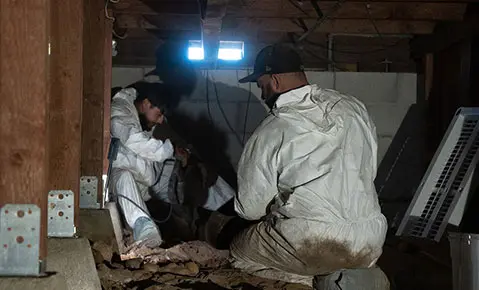

Step numero uno is to expose the footing and cracked area. This requires shovels and lots of brawn to remove the soil covering the affected area. Generally, these types of repair projects require two production crew members.

Step 2 – Grind/Sandblast Cracked Area

Once the footing has been exposed, the footing is prepped for the epoxy. To prep the footing, it is ground down or sandblasted to remove dirt, debris, or anything that would impede a solid bond.

Step 3 – Cover Exposed Rebar

Granted, this step isn’t always needed, but if there is exposed rebar we apply high-strength grout to the rebar. Carbon fiber and rebar cannot touch, because they are chemically adverse.

Step 4 – Apply Epoxy

Epoxy is applied to the crack with a small roller.

Step 5 – Apply Carbon Fiber

Carbon fiber is then applied to the epoxied crack. All slack and kinks are smoothed out during the application process.

Step 6 – Apply More Epoxy

A coat of epoxy is applied over carbon fiber. Allow this final coat to dry.

Step 7 – Return Soil

We put the dirt back and, viola, your cracked footing is good to go. Or sit, it’s not really going anywhere…

Why Carbon Fiber Footing Repair?

This process is far less expensive than removing and replacing an entire section of cracked footing. It is a perfect solution for rebar blowouts and large cracks.

The repair process is relatively quick. On a typical project for a rebar blowout (where the rebar rusts, expands, and busts out chunks of concrete) it should only take a day to repair. The larger the repair, the longer it will take.

Carbon fiber also works well for spider web cracking and vertical footing cracks, as it’s less expensive than steel straps. It can also better address a wide area due to the dimension of the fiber.

What’s the Next Step?

In this article, you learned the properties of carbon fiber and the seven installation steps to repair a cracked footing.

We understand – no one wants their property value to go down or for their home’s structural integrity to be compromised due to a simple footing crack.

We’ve been in the foundation repair industry for a while and we know how daunting it can be. Water damage can cause a slew of other problems besides a cracked footing, spalling being a key adversary.

To learn about the dangers that concrete spalling poses to your home’s foundation, read our article What is Concrete Spalling (Causes, Prevention, and Treatment).

If you haven’t had a foundation inspection yet, click our link below for a FREE inspection in our operating areas of Southern California and Arizona –