Are you noticing sagging floors, creaking floorboards, or gaps in your woodwork? If so, you might have a problem with sagging floor joists in your crawl space. This is a serious issue that needs to be addressed so that you can avoid further structural damage. The good news is that it’s possible to repair sagging floor joists. Read on to discover information on what causes sagging floor joists, how to identify them, and the best ways of fixing them to restore stability to your home.

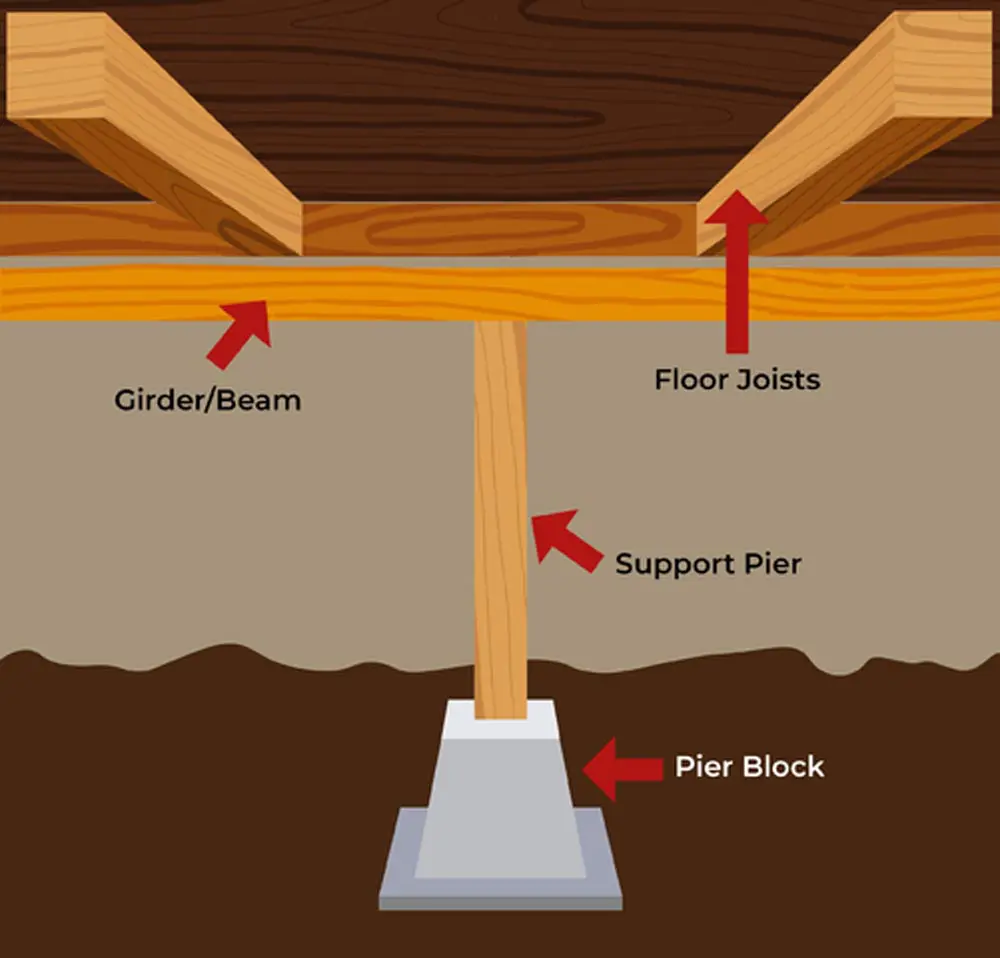

What Are Floor Joists?

Floor joists are horizontal support members that primarily function to distribute the weight of a structure and its contents downward to the beams and support posts.

Joists run parallel to each other and perpendicular to the beams, with the beams resting on top of the support posts (see the illustration below).

The size and spacing of these pieces depend on the type of floor or subflooring being installed, as well as the overall design of the structure.

What Causes a Floor Joist to Sag?

Various things can cause a floor joist to sag, including:

- Termite damage – Termites are tiny pests that feed on wood, causing structural damage that weakens the joist. If this damage isn’t addressed promptly, it can compromise the integrity of the entire structure.

- Moisture – When wood gets wet, it starts to rot and weaken, leading to sagging or bowing. We’ll talk more about crawl space moisture below, because keeping your crawl space dry is essential for a healthy foundation.

- Soggy soil – When the soil beneath the foundation becomes saturated, the support posts can settle into the ground and become non-vertical. This puts additional pressure on the joists, causing them to sag or bend.

- Inadequate support – This could occur if there aren’t enough joists, or if the joists are too small.

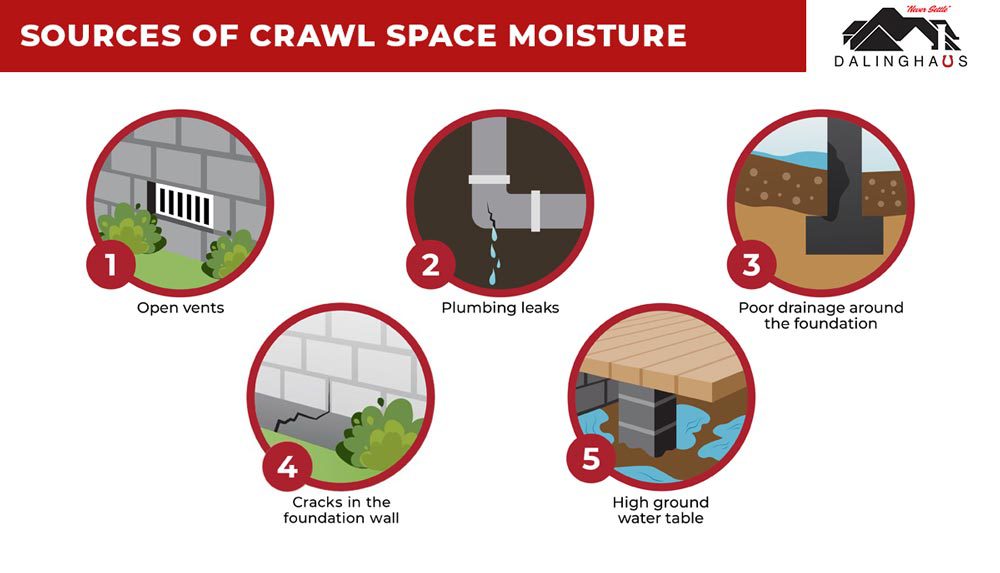

Sources of Crawl Space Moisture

The most common causes of moisture in a crawl space include:

- Open crawl space vents – While crawl space vents are initially designed to promote ventilation in the crawl space, they inevitably allow moisture-laden air to enter and condense on cool surfaces. This increases the moisture content in the crawl space, making it a breeding ground for mold and mildew.

- Plumbing leaks – Leaks from pipes running through the crawl space or from plumbing fixtures above it can result in water accumulation, creating ideal conditions for mold and mildew to grow in.

- Poor drainage around the foundation – Water pooling in the ground around the foundation will eventually find its way into the crawl space.

- Cracks in a foundation wall – Even hairline cracks can allow water to seep through a foundation wall and into a crawl space.

- High water table – A high water table can allow water to seep into the crawl space through the dirt floor.

Signs That You Might Need Floor Joist Repair

Unfortunately, many homeowners overlook the condition of their crawl space until severe damage has already occurred. Here are some common signs that you might need floor joist repair:

- Your floor is sagging or uneven.

- Your floor feels bouncy when you walk on it.

- You have wall cracks.

- Your doors and windows don’t open and close properly.

- There’s a musty smell in your home. This might indicate that moisture is present in your crawl space.

- There’s condensation inside your home. Moisture in the crawl space can lead to the development of condensation in the house.

- There’s mold on the floor or baseboards above the crawl space. This is another sign that the crawl space is full of moisture and mold.

If you notice any of the above–or anything else that strikes you as suspicious–contact a professional foundation repair contractor right away and ask for an inspection. Foundation problems that are caught early cost less to repair.

How Are Sagging Floor Joists Repaired?

When it comes to repairing floor joists, there are two main methods that are commonly used: sistering and replacing the support posts with new support posts or screw jacks.

Repairing Sagging Floor Joists Via Sistering

Sistering is the process of attaching a new joist to the side of an existing joist to reinforce it. This involves cutting the new joist to the same length as the damaged one and then securing it with construction adhesive and screws. The new joist can provide additional support and help distribute the weight of the load more evenly.

Replacing Support Posts or Installing Screw Jacks

If the existing support posts are damaged, they can be replaced with new support posts or adjustable screw jacks. This involves jacking up the affected section of the floor, removing the old posts, and then installing new ones in their place. Screw jacks are adjustable, making them a popular choice for repairing sagging or uneven floors–and in the event that you experience further settlement, the screw jacks can simply be adjusted.

What About DIY Sagging Floor Joist Repair?

Floor joist repairs should only be carried out by a licensed professional, as incorrect installation or inadequate reinforcement could result in serious safety hazards. A professional foundation repair contractor can assess the condition of your floor joists and recommend the best course of action to ensure the structural integrity of your home.

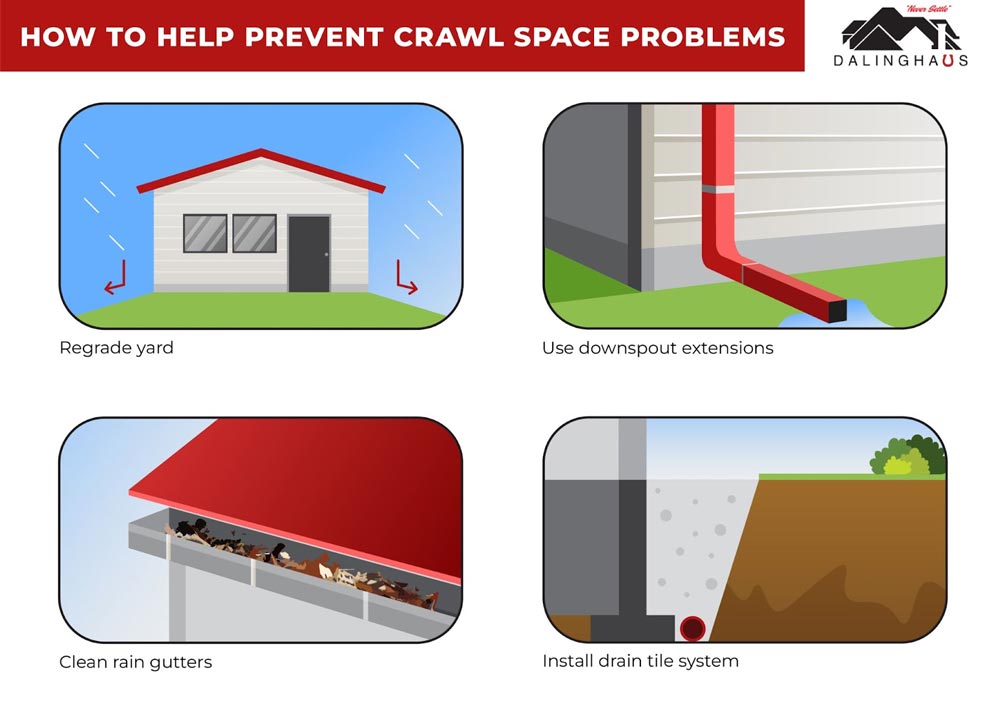

Tips on How to Help Prevent Crawl Space Problems

Fortunately, there are several effective measures property owners can take to help prevent crawl space problems from occurring in the first place. Note that all of these involve controlling groundwater around the foundation in order to help ensure the crawl space remains dry:

- Regrade your yard, if necessary – This simple technique involves sloping the ground away from the foundation, which will help prevent groundwater from draining toward the foundation.

- Install downspout extensions – These are inexpensive, easy to install, and will direct runoff away from the foundation before release.

- Clean gutters regularly – Cleaning gutters regularly can help prevent clogs that can cause water to back up and overflow near the foundation.

- Install a drain tile system – A drain tile system collects water and guides it away from the foundation, ensuring that the ground around the foundation remains dry.

For more information, see our articles Why Closing Crawl Space Vent Covers Only Isn’t Enough and Is Standing Water in a Crawl Space Normal?

If you’re concerned that there might be a problem with the floor joists in your home’s crawl space, contact us today to schedule an evaluation. We serve Southern California, Arizona, and Nevada.