It’s crazy to think that there is a foam that can stabilize a building and is capable of lifting a home or business… quite literally. Polyurethane foam has been used in the foundation repair industry for a few decades, being able to densify soil and stabilize buildings (alongside other repair methods) that deal with foundation settlement.

But can Polyurethane foam be used to stabilize a building on its own? Well, that depends on the circumstances.

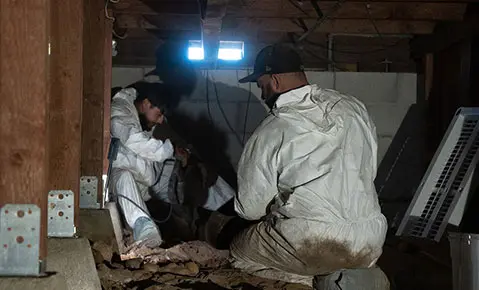

Dalinghaus Construction has been in the foundation repair industry since 2015 in Southern California, Arizona, and Nevada, using a variety of foundation repair methods for over 2,000 projects, especially with the application of Polyurethane foam. We understand how this stuff works and when it’s most appropriate to apply it.

What is Polyurethane Foam?

Polyurethane sounds like a complex chemical that would turn people into zombies. Or an off-brand version of propane. Either way, it’s not as scary of a substance as people think.

Polyurethane is a combination of compounds composed of polyol and diisocyanate – a resin and isocyanate. When combined, they create a solid foam that expands rapidly, cures in 15 minutes, can be as hard as (and is 97% lighter than) concrete, is water resistant, and is environmentally safe.

You’ll see polyurethane foam used for deep injection for applications such as soil densification, void fill, and releveling.

Polyurethane has a deep history and multitudes of applications, even though it’s relatively new in the foundation repair industry.

Polyurethane foam is safe for the environment

Again, this stuff won’t contaminate the soil or kill the plants in your garden. Polyurethane is used in areas like shoes, mattresses, insolation, and even pacemakers, which go in your body. The scary word isn’t actually an intimidating thing.

If you’re still not convinced, read our article on why you don’t need to worry about polyurethane foam being dangerous.

Polyurethane foam applications

Void Fill and Structural Support

This one is pretty straightforward. If there are voids or micro voids in the soil, they will be filled to stabilize your slab-on-grade foundation home or business, especially after foundation leveling.

The soil will be densified under a structure to offer additional support on top of a push pier and helical pier underpinning system.

Releveling

It’s hard to believe foam can lift a building, huh? Yeah, it’s both nuts and possible. Polyurethane foam expands in all directions when the expansion process happens.

Many injection tubes are put into the ground that injection guns are attached to. The Polyurethane foam will be injected and will gradually raise a building a little bit.

Don’t expect this stuff to lift 16 inches. That’s a whole bunch of polyurethane your would need.

Funny enough, there have been situations where Polyurethane foam was better suited to lift compared to the pier systems. It doesn’t happen often, but there have been those occasions.

When the foam has nowhere to go, it expands and gets a better lift.

Polyurethane can also relevel concrete. That way you don’t have to remove or replace settling concrete.

Can polyurethane foam stabilize my home or business without push pier or helical pier underpinnings?

Yes, but it ultimately depends on the circumstances of the foundation issue you’re dealing with. Don’t expect Polyurethane foam for your particular situation to be the recommended solution.

For instance, some soils don’t permeate and mix as well with polyurethane. Sandy soil is excellent for polyurethane foam to permeate through. Clay soil is a little bit different story. The clay soil will be pushed in all directions while the polyurethane turns into a giant blob.

Polyurethane in clay soil can support a building on its own if it’s done correctly. Putting them in increments and stacking them on top of each other until it reaches the foundation can work. The issue is that quite a lot of chemicals would be used to create the polyurethane foam. With the cost being around $110 per square foot, you might as well have gone with a push pier or helical pier underpinning with poly.

You don’t want to dump foam into the ground if the solution isn’t optimal for your situation. Even if it can work, other options might be more practical and cost-effective.

It depends on what you want to do for your foundation repair

There was a project I worked on with a gentleman a while back with a homeowner that wanted to raise their home that had settled three inches using Polyurethane foam. I said we could do a lift, but we may only be able to get a half inch, but I couldn’t guarantee a three-inch lift.

His neighbors had their water runoff go to their property line, which inevitably causes soil to erode. It just so happens his home was right where it was sinking.

So even if everything was lifted with Polyurethane foam, the water can continue to do damage to the soil around it. There’s nothing to worry about with the foam since it’s water resistant, but the damaged soil could ultimately cause a home to sink again.

In that particular case, a more permanent solution was galvanized steel Push pier or Helical pier underpinnings for the home.

When these piers make it to loadbearing strata or bedrock, the soil can move all it wants since the load is transferred to an in-bearing system. Think of this underpinning system as acting like stilts. Remove five feet of soil from under the home and the piers should still hold everything up as though nothing happened.

Stabilizing using only polyurethane foam might not be your optimal solution to your foundation issues, especially if your home or business is on a hillside. You’ll want a more permanent solution rather than something temporary.

You want your job done right the first time

The whole point of foundation repair is to ensure your home or business will no longer be affected by foundation issues. Sure, Polyurethane foam without a piering system can be a solution, but that’s never a guarantee. It depends on the circumstances.

We want your foundation to be a permanent solution. Temporary solutions won’t help you or your wallet in the long run.

Schedule a foundation inspection with a professional that can offer you permanent solutions

You’ve learned about polyurethane foam, its applications, if it can stabilize your home or business without piers, and what you need to consider for your foundation repair. You want to make sure your foundation repair is a permanent solution the first time. Using only Polyurethane foam on its own might only help you temporarily.

Dalinghaus Construction has helped thousands of home and business owners with more than solutions involving Polyurethane foam. We want to find the best solution to fit your needs.

Learn more about other foundation repair solutions such as crawlspace foundation repair, and the applications of Polyurethane foam

If you live in Southern California, Arizona, or Nevada, book a free 60-90 minute foundation inspection to see which repair is best for you.

You can schedule your appointment by calling Dalinghaus Construction at (877)360-9277 or clicking the link below.