Do you have a sinking slab that needs a lift? There are two primary lifting services in the construction industry capable of lifting, stabilizing, and leveling your foundation/flatwork: polyurethane injection and mudjacking/slab jacking.

If you read our blog, keep up with our Instagram, or watch our Youtube channel, then you’ve undoubtedly heard a lot about polyurethane…but not much about mud jacking.

This is because we tend not to write extensively on services we do not provide – however, in this article, we are going to analyze the 3-key benefits of poly over mudjacking:

- Lighter Weight

- Smaller Hole Size for Application

- Faster Cure Time

What is Mudjacking? Mudjacking is the lifting or leveling of a structure, driveway, or slab of concrete by pumping a mixture of slurry (with incredibly high pressure) underneath a sunken slab. |

Polyurethane has Lighter Weight

Polyurethane weighs 2-4 pounds per cubic foot. Mud can weigh as much as 100 pounds per cubic foot. Weight is important because it can act as an anchor, sinking an already settling ship.

Polyurethane can help stabilize soil by adding rigidity – mudjacking simply packs on more weight. Yes, mudjacking is extremely effective at lifting settled flatwork and is attractive because of its relatively cheap cost, but it is not a long-term solution.

The mud will eventually settle into the expansive soil.

Polyurethane floats on expansive clays and only settles when the soil beneath it gives way. Polyurethane is lightweight, dense, and incredibly strong.

Polyurethane relies on the expansive pressure for the lift. Mudjacking relies on installation pressure.

Fun Facts with Brian – Polyurethane expands kind of like shaving cream after leaving a can, allowing it to fit perfectly into crooks and crannies as it balloons outward.

Polyurethane Utilizes Smaller Application Holes

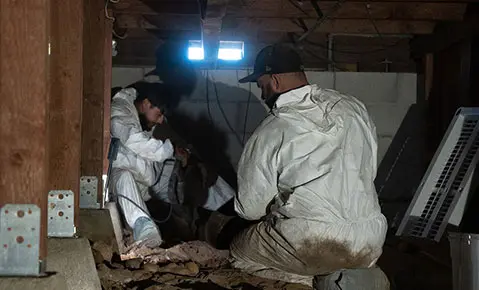

Polyurethane and Mudjacking follow the same three-step system: Drill, Pump, Patch.

The biggest difference in the system itself is the size of the application hole.

Poly & Mudjacking’s Three Steps –Drill – Drill into the concrete (often in a grid pattern)Pump – Void fill the hole with a slurry application gunPatch – Patch holes and color code the concrete to match |

The polyurethane injection site hole is only 5/8”, whereas mudjacking injection holes are 2 to 3 inches.

Unless you want your driveway looking like a Dalmatian, we suggest utilizing polyurethane. The patched injection sites are far less noticeable.

In addition, mudjacking can prove a bit of a mess, with excess slurry slurping out of cracks and crevices. The polyurethane foam, once dry, is easy to square off with a boxcutter.

Polyurethane has a faster Cure Time than Mudjacking

Polyurethane cures quickly, solidifying up to 90% full strength in 15 minutes. The slurry shot underneath the slab is never exposed to sunlight (thus taking a much longer time to cure).

The truth is: slurry can take several days to a week to dry. And, fun fact about concrete, it never really fully cures.

Polyurethane Warranty

Most mudjacking is not covered by warranty because it is already fairly inexpensive and it’s almost doomed to fail from the get-go.

Just because mudjacking has a cheaper price tag does not mean it has more value.

Most construction companies that utilize polyurethane have a warranty of 5 years, including Dalinghaus Construction Inc. If you would like to learn more about our lifetime warranty on steel pier systems.

Why Choose Polyurethane Injection?

Polyurethane is lightweight, easy to install with little chance of a mess, and cures incredibly fast. Mudjacking, on the other hand, is not a permanent fix, can sink your flat-work, and rarely has a warranty tied to it.

If you live in Southern California or Central Arizona and would like a FREE void fill inspection, click the link below.